Our primary concern is to achieve maximum rigidity and strength while maintaining optimal weight and balance. This is the equation that explains the high levels of safety you can expect of our yachts in all conditions.

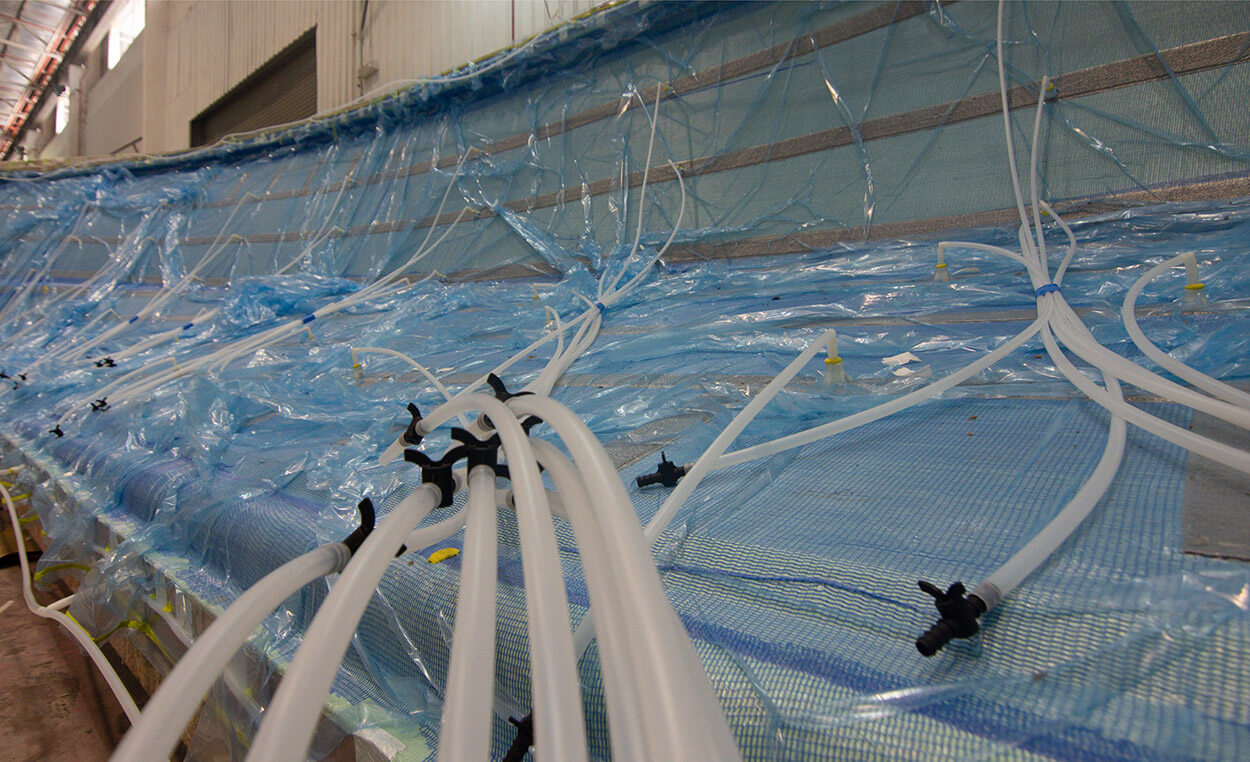

The hull is formed from a ‘sandwich’ of premium grade e-glass with a water resistant, closed-cell foam core. This highly buoyant combination is then vacuum infused with Vinylester in a process that ensures the perfect ratio of resin to material.

Using a similar infusion process, the deck and superstructure are formed from unidirectional carbon fibre that delivers the best possible combination of strength and weight reduction.

Once released from the moulds, the transparent gel coat that covers the glass fibre is then ready for painting and finishing.

We are detail fanatics and we’re proud of it!

If good is the enemy of great, we believe great is the enemy of perfection and that’s the standard we strive to achieve.

You’ll find evidence of this philosophy in every nook and cranny of our yachts. For example, all of the teak we use is book matched to ensure consistency of grain and colour. (If it fails to meet those standards, we don’t use it.) You’ll find all bolts have been torqued to ensure that the correct tension is visibly maintained.

Duck into the engine room and you’ll find that the arrangement of every pipe and conduit is equidistant and perfectly parallel. You can scrutinize any element of the build and you’ll find that we’ve scrutinized it before you.

Repeatedly!</p

A Palm Beach Motor Yacht is a thing of great beauty and we find our owners take great pleasure in ensuring that they stay that way.

We do our best to help.

Knowing how unkind the elements can be, we no longer use timber on our foredecks and we provide full canvas covers for those areas where teak is likely to be exposed.

You’ll find a typical maintenance schedule requires a wash and wax every two weeks and an anti-foul every twelve months. Engines, be they Volvo or Caterpillar, are covered by a five-year warranty and need servicing every year or every 100 hours of running time.

Should you have any questions or encounter any difficulties, we provide a friendly concierge service that’s on call to give advice and steer you in the right direction.